Liquid Waste Management Equipments

LIQUID WASTE MANAGEMENT EQUIPMENTS

Sewer Suction Machine

The combined High Pressure Jetting and Sewer Suction Machine is suitable for Dislodging and removing obstruction and blockages from Sewer line by High Pressure Water Jetting System and suctioning the sludge/slurry from sewer manhole, gulley pit, septic tank etc. by Vacuum Suction System and discharge the collected sludge by hydraulic tipping of the container or by blowback arrangement. The suction cum jetting machine with recycling facilityshall be mounted of a 9 T GVW Truck Chassis.

These equipments are being deployed for the cleaning of Septic Tanks as well as sewer pipelines upto 900 mm diameters. These machines are designed and developed to perform suction and jetting activities accurately.

A Recycler Machine is a cutting-edge piece of technology designed to promote environmental sustainability and reduce waste. This innovative device serves as a powerful tool in the ongoing battle against pollution and resource depletion. Recycler Machine is equipped with advanced sorting, cleaning, and processing mechanisms, capable of efficiently handling a wide range of recyclable materials, such as plastics, glass, paper, and metals. By automating the recycling process, these machines significantly reduce the burden on human labour, while also improving the quality and quantity of recycled materials. As a result, Recycler Machine plays a vital role in fostering a greener future, where recycling is not only convenient but also a key component in the global effort to conserve natural resources and mitigate the impact of climate change.

Our recycler machine is designed keeping in mind the specific requirements of liquid waste management for the municipal corporation. We leverage the highest quality materials and technologies to develop the best recycler machine for the customers. Our team of expert professionals are committed to delivering optimum value to the customers.

- Optimum Performance

- Robust Construction

- Longer Service Life

Sewer Suction Cum Jetting Machine

The Heavy Duty Truck Mounted Vacuum Loader with High Pressure Jetting System is suitable for dislodging the Silt/Sludge settled in the trunk sewer lines and for suctioning the free flowing sludge and slurry for De-silting the trunk Sewer Pipelines.

The suction cum jetting machine with recycling facility is one of the most efficient and powerful machine of its kind available in the International Market, incorporating state-of-art Filter System, positive displacement Vacuum Pump driven through an Auxiliary Engine, Jetting Pump and Control System.

A Suction cum Jetting Machine with recycling facility is a cutting-edge piece of equipment designed for efficient and environmentally responsible cleaning and maintenance of various industrial and municipal infrastructures. The suction cum jetting machine with recycling facility operates in conjunction with Truck Mounted Cyclonic Sludge/Silt Container/Dump Tank. Generally, two dump tanks are used with one Vacuum Loader Machine.

The Vacuum Loader Machine and the Dump Tank are connected together with a connection hose. The Silt/Sludge suction from the manhole is collected in the Cyclonic Sludge/Silt Container/Dump Tank.

When one tank is full, it goes to the Dumping Ground for discharge of material and the 2nd sludge tank is connected to the Vacuum Loader. In this manner, the Suction activity continues without interruption.

However, a sludge tanker is a specialized vehicle designed for the transportation and disposal of sewage and wastewater sludge. These robust and often large sludge tanker trucks play a crucial role in the sanitation and environmental industry by efficiently collecting and transporting the residual by products of sewage treatment processes. Sludge tanker is equipped with sealed, high-capacity tanks to prevent leaks and odours, and they typically have powerful vacuum systems to facilitate the suction and loading of sludge from treatment plants or septic systems. The sludge tanker is constructed with features such as anti-corrosive materials and sealing mechanisms to prevent leaks and emissions, promoting both safety and environmental responsibility in the handling of sludge materials. Once filled, sludge tanker transports the sludge to designated treatment or disposal facilities, where it can be processed, treated, or safely disposed of, contributing to the overall maintenance of public health and environmental quality.

We have expert personnel in our organization working round the clock to offer high grade Suction Cum Jetting Machine. These machines are designed and developed to perform diversified activities of suction and jetting accurately. Our suction cum jetting machines are reckoned internationally for their reliability and consistency.

- Optimum Performance

- Robust Construction

- Longer Service Life

De-silting Machines (Super Sucker)

The super sucker machine is designed for cleaning and maintenance our Sewer Pipelines. The equipment is a combination of suction machine and the Jetting Machine with Sewer Water and filtration a Recycling facility mounted on 16Ton GVW Truck Chassis.

The main advantage of the super sucker machine is that the Water Suction from the Sewer lines is filtered/cleaned in multiple stages and is used for jetting purposes. The super sucker machine, therefore, does not required fresh water for carrying out the jetting operation and jetting operation can be carried out without interruption for long duration and is not limited by the Capacity of the fresh water tank as is the case of normal Suction-cum-Jetting Machine or a De-silting Machines.

The super sucker machine has a tank Capacity of 7000 Ltrs. is mounted on a 16T GVW Truck Chassis with small wheel base and is suitable for cleaning the Sewer Line in the lanes and by lanes in the City, where larger machine mounted on 25Ton GVW Truck Chassis cannot operate.

These Equipments are used for suction of silt/stones from the underground trunk sewer pipelines of diameter ranging from 1 meter to 3 meters. The Trunk Sewer pipelines are installed about 7 to 8 meters below ground level.

TPS is manufactures one of the most powerful Vacuum Loader Machine, which is being utilized for De-Silting of Trunk Sewer pipelines for Silt, Bricks etc. A number of Service Providers are using specialized Silt container trucks along with De-Silting machines, wherein the silt is separated and collected in these Silt Container trucks, which ultimately go to the dumping ground for discharge.

These units are developing vacuum of 8000 mm water column and air handling capacities ranging from 4000 to 6000 Cu.M/hr. A number of such machines are deployed in various parts of India for undertaking De-Silting work

Suction cum jetting machine with Sludge Water Recycling

The equipment is designed for cleaning and maintenance of our Sewer Pipelines. The equipment is a combination of suction machine and the jetting machine with sewer water and filtration a recycling facility mounted on 25Ton GVW Truck Chassis.

The main advantage of the above machine is that the Water Suction from the Sewer lines is filtered/cleaned in multiple stages and these used for jetting purposes. The machine, therefore, does not required fresh water for carrying out the jetting operation and jetting operation can be carried out without interruption for long duration and is not limited by the Capacity of the fresh water tank as is the case of normal Suction-cum-Jetting Machine or a De-silting Machines.

The above equipment is provided with a higher capacity vacuum pump and Jetting Pump is mounted on a 25T GVW Truck Chassis is suitable for cleaning the Sewer Line in the City.

- Most advanced Sewer line Maintenance Equipments incorporating a combination of Suction and High Pressure Jetting System with Sewage Water Filtration facility for the Jetting System.

- Used for Flushing Sewer pipelines and de-silting the manholes/chambers in the sewer lines.

- Heavily silted sewer lines of various sizes can be cleaned with the help of high pressure water jets produced by the jetting system and the silt accumulated in the sewage lines including plastic bags, stones, etc. shall be sucked simultaneously by the suction system from a depth of 7 ~ 10 Mtrs.

- The unit utilizes the recycled filtered water from the sewage water suctioned from manholes, for jetting purpose. The equipment does not require Fresh Water for Carrying out Jetting Operation.

The Jetting operation can be carried out WITHOUT INTERRUPTION for long durations and is not limited by the capacity of the fresh water tank, as is the case of normal suction-cum-jetting machines.

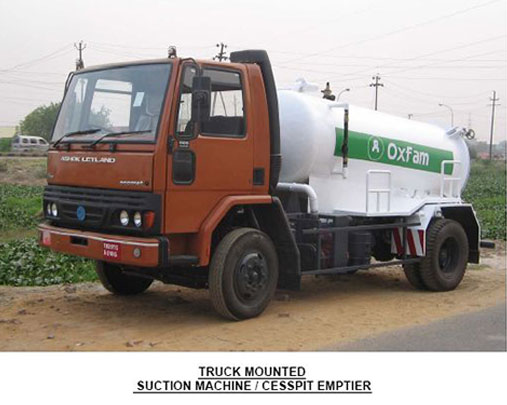

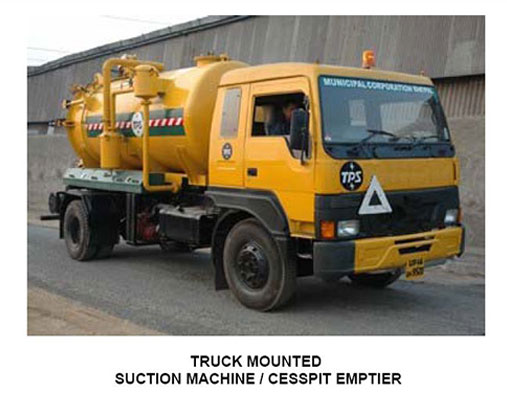

Cess Pit Emptier

The equipment is a truck mounted mobile unit suitable for suctioning the sludge / slurry from sewer manholes, gully pits, septic tanks etc. by vacuum suction system and discharging the collected sludge of the tank, alternatively through blow-back arrangement.

The suctioned sludge that is collected, is put in a truck mounted Suction Dump Tanker with cyclone, for onwards disposal at dumping grounds